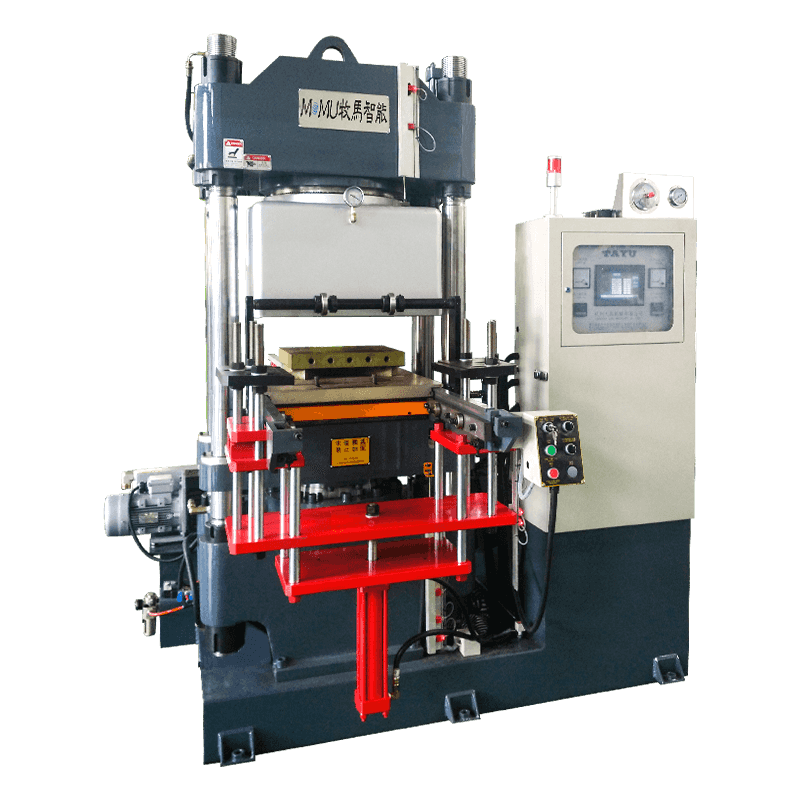

The rubber injection molding machine is an advanced production equipment that is widely used in the rubber products industry, such as the manufacture of auto parts, seals, rubber pipe fittings, etc. This article will deeply explore the working principle, technological innovation, application fields and future development prospects of rubber injection molding machines, and fully demonstrate the importance and potential of this key manufacturing process to readers.

The rubber injection molding machine uses a modern injection molding process and its working principle is similar to plastic injection molding. It mainly includes the following steps:

Raw material pretreatment: Rubber particles undergo pretreatment processes such as mixing, heating, and plasticization to reach a flow state suitable for injection molding.

Injection: The heated rubber is injected into the mold cavity through a screw or plunger injection system to form the desired product shape and structure.

Curing: After injection in the mold, the rubber begins to solidify and cool, allowing it to maintain the desired shape and size.

Mold opening and removal: After curing is completed, the mold is opened and the finished product is taken out of the mold and prepared for the next round of production.

![]()

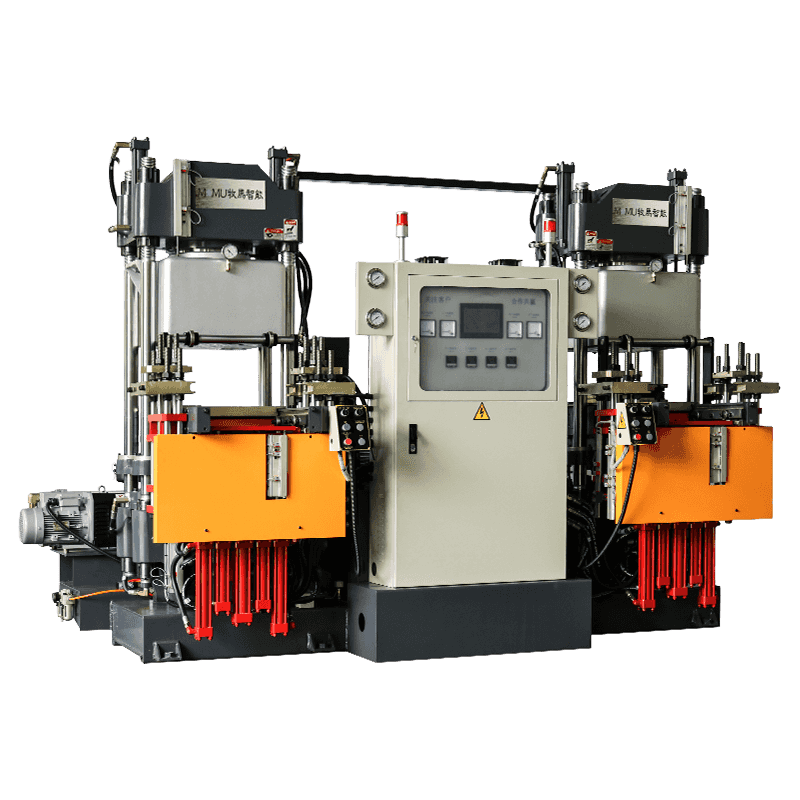

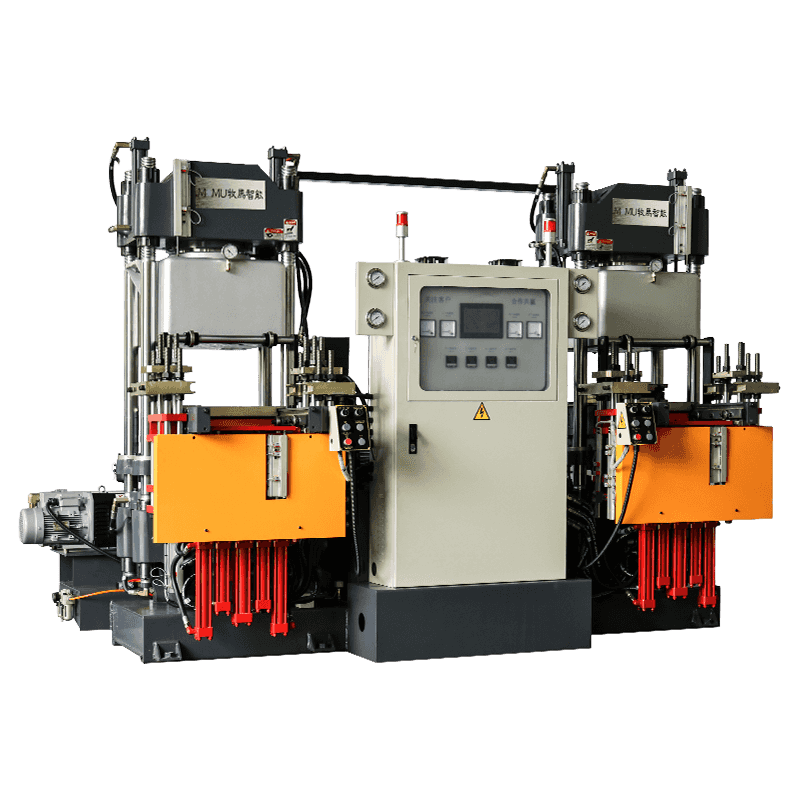

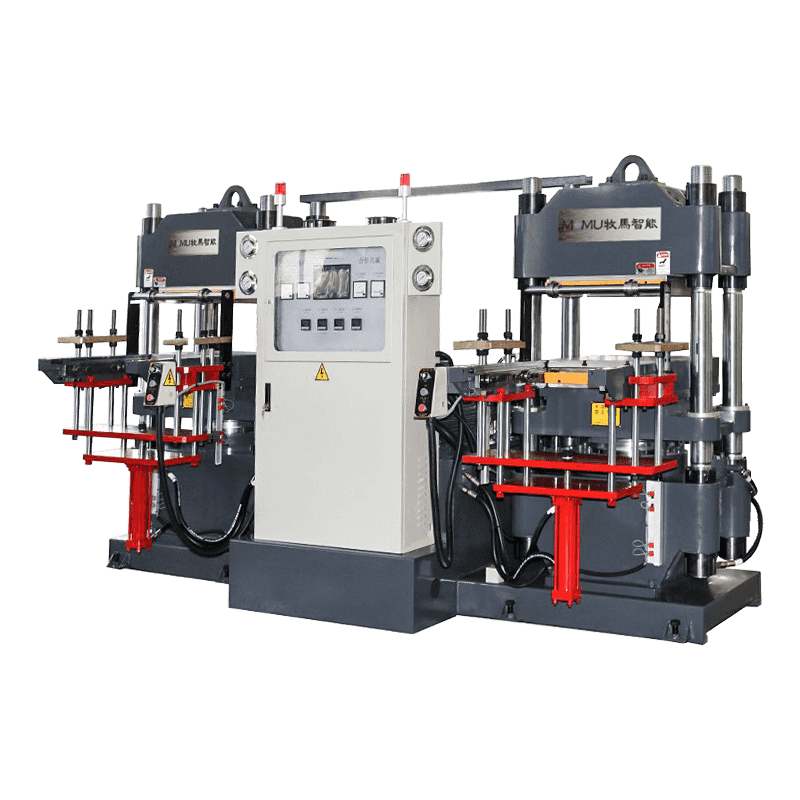

With the continuous advancement of technology, rubber injection molding machines are also constantly undergoing technological innovation to meet market demand and improve production efficiency. Some major technological innovations include:

Intelligent control system: Introduce advanced intelligent control system to realize real-time monitoring and adjustment of production parameters and improve production stability and consistency.

High-precision injection system: Adopt a precise injection system and advanced flow channel design to achieve precise injection and filling of rubber materials, improving product quality and molding accuracy.

Energy-saving and environmentally friendly technology: Optimize equipment structure and energy utilization, reduce energy consumption and waste gas emissions, improve production efficiency and reduce environmental impact.

Multifunctional mold design: Develop multifunctional molds to mold multiple products at one time, improve production flexibility and efficiency, and reduce production costs.

Rubber injection molding machines are widely used in many fields, including but not limited to:

Auto parts manufacturing: Rubber injection molding machines can be used to produce key parts such as automotive seals, suspension systems, rubber pipe fittings, etc., providing excellent sealing performance and durability.

Electronic and electrical industry: In electronic and electrical products, rubber injection molding machines can be used to manufacture rubber parts such as keyboards, seals, cable joints, etc., to meet the waterproof and dustproof requirements of the products.

Engineering machinery field: Rubber injection molding machines can manufacture wear-resistant and pressure-resistant rubber parts such as excavator tracks, vibrating screens, rubber pipe fittings, etc., to improve the service life and performance of engineering machinery.

Medical device manufacturing: In the field of medical devices, rubber injection molding machines can be used to produce medical pipe fittings, seals, handles and other rubber parts to meet the health and safety requirements of medical equipment.

With the development and technological advancement of the global manufacturing industry, the rubber injection molding machine market has broad prospects. Future development trends include but are not limited to:

Intelligent manufacturing: Intelligent and automated rubber injection molding machines will become mainstream, improving production efficiency and product quality.

New material application: With the continuous emergence of new materials, rubber injection molding machines will expand new application areas to meet the needs of different industries.

Customized production: Personalization and customization of customer needs will promote the development of rubber injection molding machines in the direction of flexibility and customization.

Environmentally friendly technology innovation: Rubber injection molding machines that focus on energy conservation and environmental protection will be more widely used to meet environmental protection regulations and market demand.

As a key production equipment, rubber injection molding machine plays an important role in the manufacturing industry. With the continuous innovation of technology and the continuous expansion of the market, rubber injection molding machines will continue to play an important role in providing technical support and guarantee for the development of various industries.