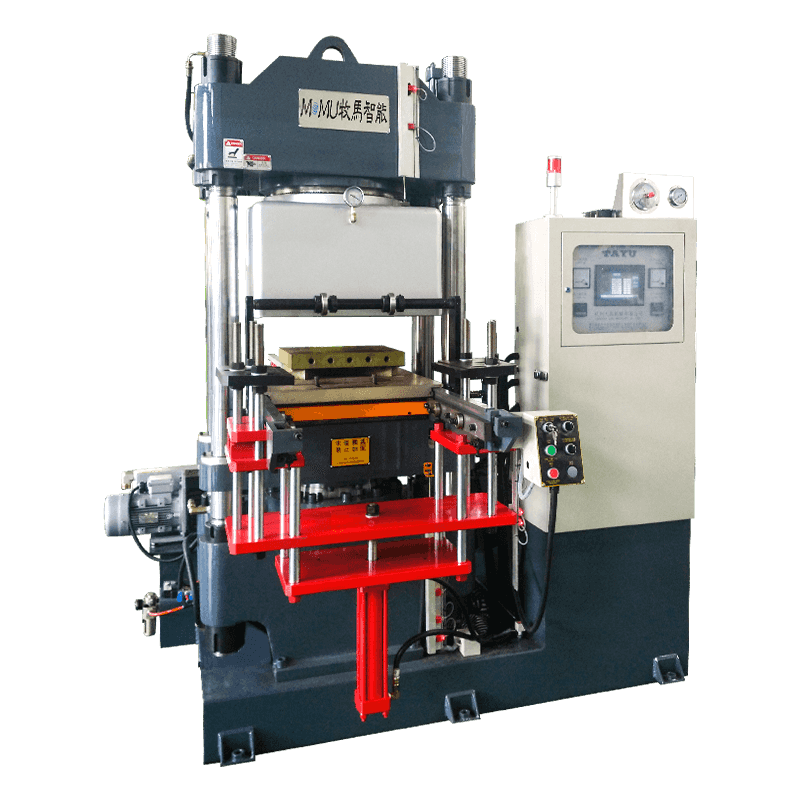

The precision of an insulator machine in controlling product dimensions and ensuring quality depends on several factors related to its design, construction, and operational capabilities. Here are key considerations regarding the precision of an insulator machine:

Factors Influencing Precision

Control Systems and Sensors:

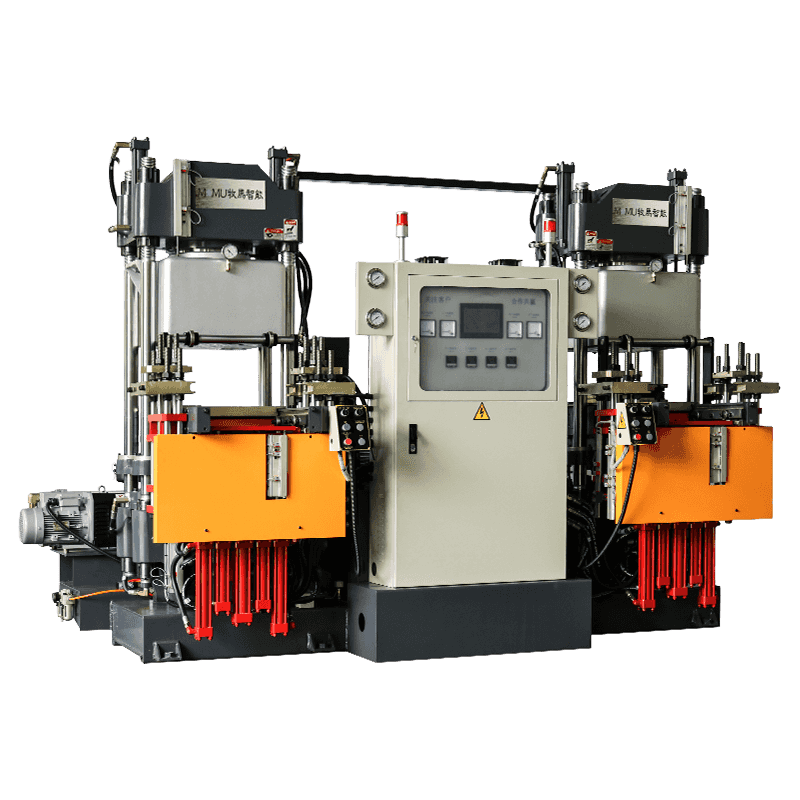

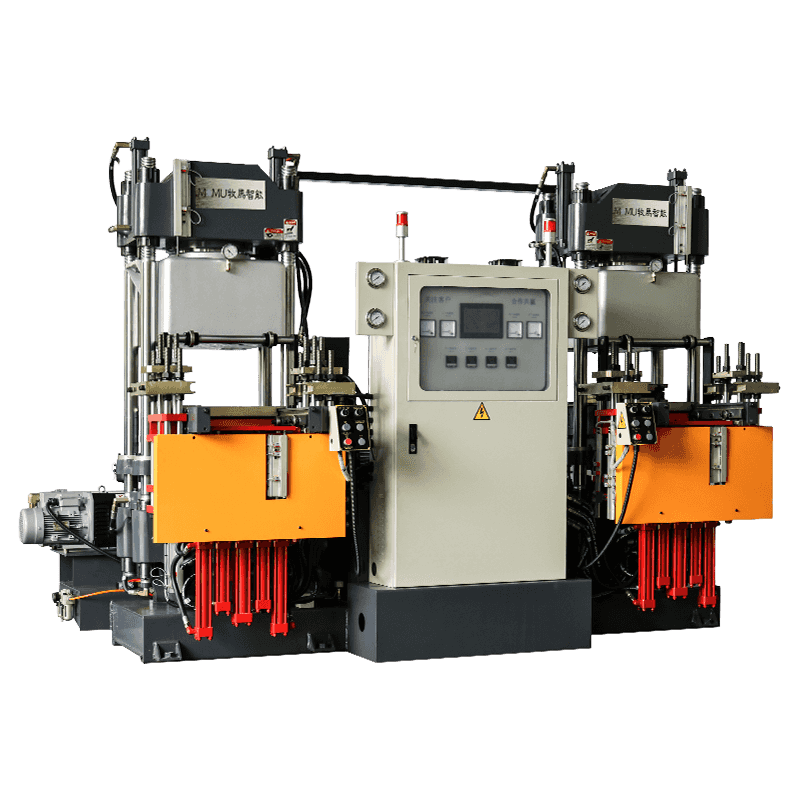

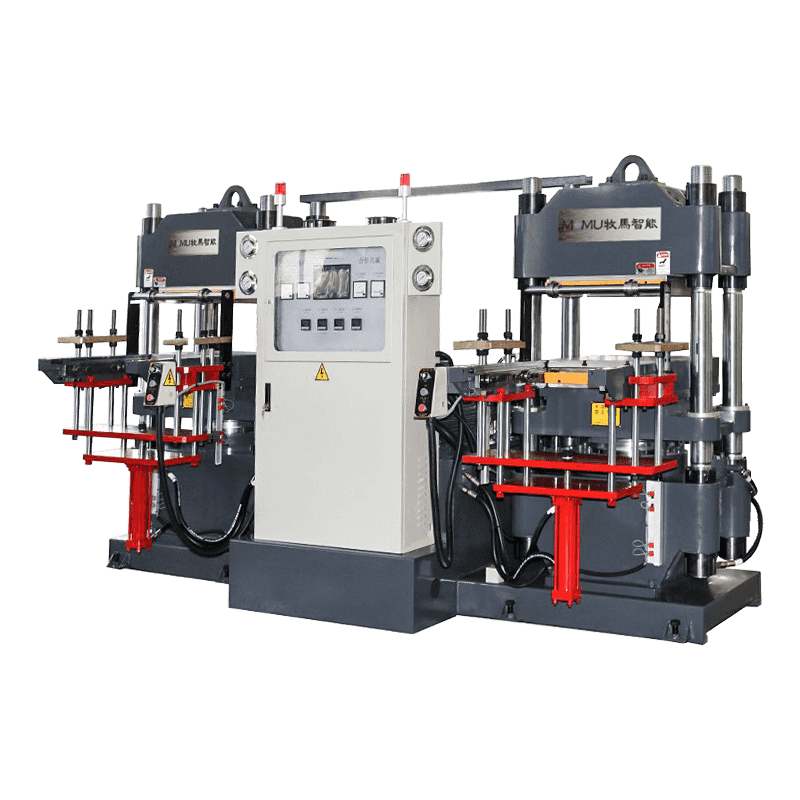

Insulator machines equipped with advanced control systems, such as programmable logic controllers (PLCs) or computer numerical control (CNC), offer precise control over manufacturing parameters.

Sensors integrated into the machine provide real-time feedback on material thickness, tension, and alignment, allowing for adjustments to maintain dimensional accuracy.

![]()

Material Handling Mechanisms:

Automated material feeding and handling systems ensure consistent material positioning and feed rates, which are critical for maintaining product dimensions.

Precise cutting mechanisms, such as rotary blades or laser cutters, contribute to achieving accurate product dimensions and clean edges.

Thickness Control:

Insulator machines may feature automated thickness control mechanisms that adjust the compression rollers or pressing force based on preset specifications.

This ensures uniform thickness throughout the insulation material, reducing variations and maintaining quality.

Alignment and Registration:

Proper alignment and registration systems ensure that the insulation material remains aligned correctly during the manufacturing process.

This prevents misalignment or skewing, which can affect product dimensions and quality.

Measurement and Feedback

Quality Assurance Systems:

Some insulator machines are equipped with integrated quality assurance systems that perform in-process inspections.

These systems may use optical scanners, cameras, or laser sensors to detect defects, dimensional variations, or irregularities in the produced insulation.

Tolerance and Accuracy:

Manufacturers specify tolerances for product dimensions and quality parameters.

Insulator machines capable of meeting tight tolerances ensure consistency in product dimensions and adherence to quality standards.

Operator Intervention

Operator Monitoring and Adjustment:

Operators monitor the machine's performance and may intervene to adjust settings or parameters based on observed deviations or quality issues.

Their expertise ensures that any variations in product dimensions are promptly addressed to maintain quality standards.