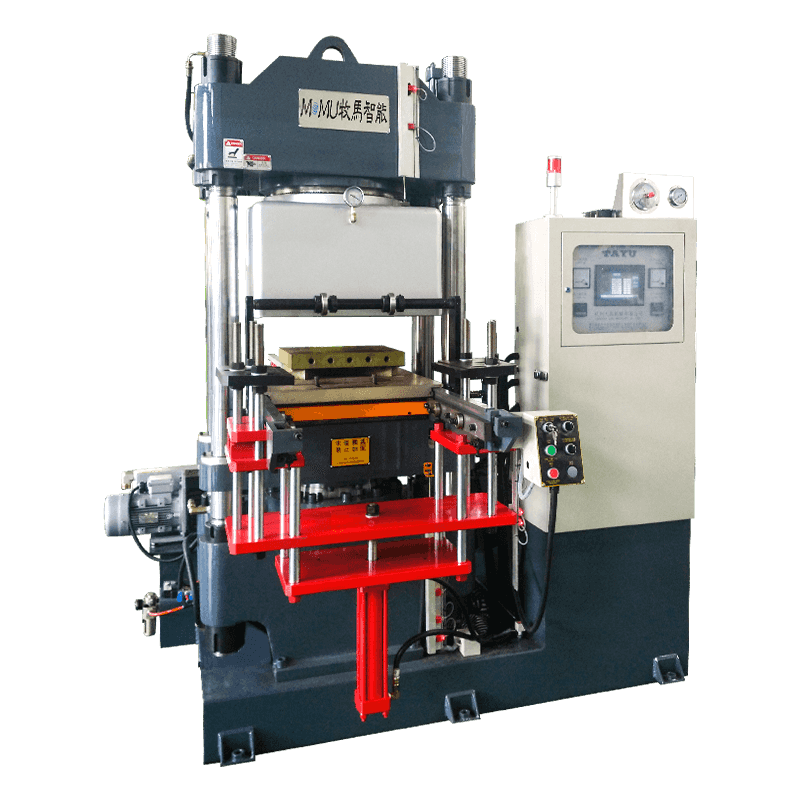

With the continuous advancement of industrial manufacturing technology, LSR liquid silicone injection molding machine, as a high-precision and efficient production equipment, is increasingly widely used in many fields. Liquid silicone has become an important material in the medical, automotive, electronics and other industries due to its excellent elasticity, high temperature resistance, UV resistance and other characteristics. The birth and continuous optimization of LSR injection molding machines provide strong technical support for the widespread application of liquid silicone.

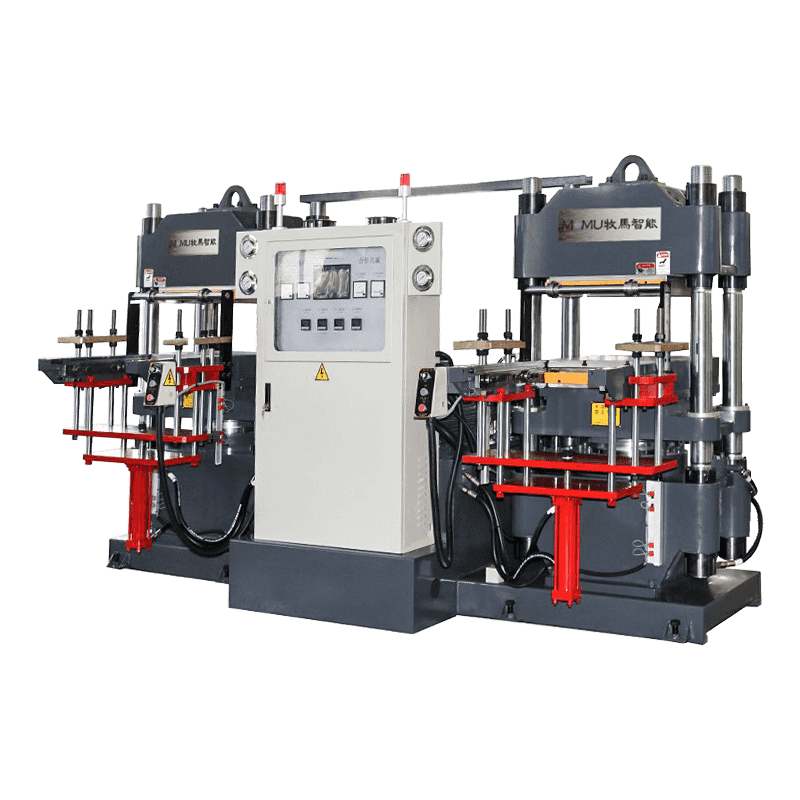

LSR injection molding machines can perform injection molding of liquid silicone in high-precision molds to ensure the dimensional stability and surface finish of the product. Especially in the production of precision parts such as medical devices and electronic products, the high-precision molding technology of LSR injection molding machines is particularly critical.

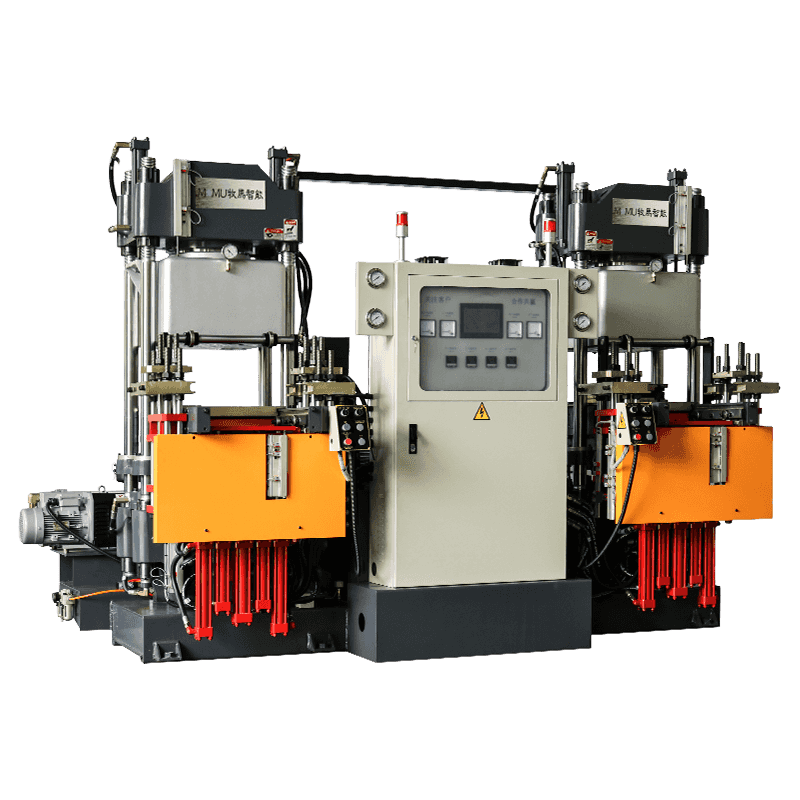

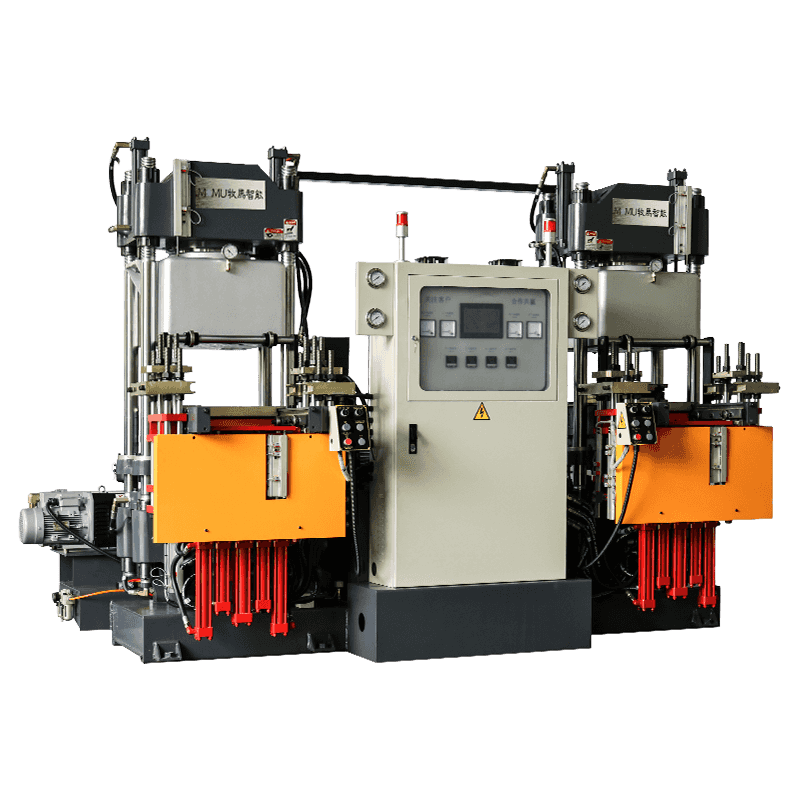

Compared with traditional silicone molding methods, LSR injection molding machines have higher production efficiency. The injection molding process of liquid silicone is relatively simple and can be quickly cured, which greatly shortens the production cycle and meets the needs of modern industry for efficient production.

LSR injection molding machines can handle different types of liquid silicone, including single-component and two-component liquid silicone materials, to meet different industrial needs. In addition, LSR injection molding machines can also be composited with other materials to produce components with a variety of different material combinations to meet increasingly complex market needs.

![]()

Liquid silicone itself is an environmentally friendly, non-toxic material that complies with international environmental regulations. The use of LSR injection molding machines helps reduce waste generation during the production process, and the finished materials are odorless and have strong antibacterial properties. They are widely used in food, medical and other fields and meet strict safety standards.

Liquid silicone is widely used in the medical industry because of its strong biocompatibility and good antibacterial properties. LSR injection molding machines can efficiently and accurately produce various medical device components, such as disposable syringe seals, artificial joints, respiratory tubes, etc. These products require a high degree of safety and precision, and LSR injection molding machines just meet this demand.

In automobile manufacturing, LSR injection molding machines are used to produce automotive seals, gaskets, lamps and other parts. Liquid silicone has good high temperature resistance and UV resistance, making it an ideal material for key components in the automotive industry.

As electronic equipment becomes more and more sophisticated and intelligent, the application of liquid silicone materials is becoming more and more common. LSR injection molding machines are widely used to produce waterproof seals for smartphones, protective covers for electronic components, and housings for sensors, etc., to meet the production needs of high precision and high reliability.

LSR injection molding machines are also widely used in the consumer goods industry, especially in the production of children's toys, kitchen supplies, and personal care products. The safety and softness of liquid silicone make it an ideal material for these products.

With the continuous upgrading of the global manufacturing industry, the market demand for LSR injection molding machines continues to increase. It is expected that by 2027, the LSR injection molding machine market will show a steady growth trend, especially in Asia, where the market demand for LSR injection molding machines will further increase due to the rapid development of industries such as medical, automotive, and consumer goods.

Although LSR injection molding machines have broad prospects, they still face some challenges. First, the initial investment of LSR injection molding machines is high, and companies need a longer payback period. Secondly, the procurement cost of liquid silicone materials is high, which to a certain extent limits the application of some small companies. At the same time, with the development of technology, how to further improve production efficiency and reduce costs has become an urgent issue for LSR injection molding machine manufacturers.

As the core technology in the liquid silicone industry, LSR injection molding machines are bringing changes to multiple industries. With the growth of market demand and the continuous advancement of technology, LSR injection molding machines will continue to play an important role in promoting the widespread application of liquid silicone materials in the fields of medical, automotive, electronics, etc. In the future, the innovation of LSR injection molding machines will not only be reflected in product quality and production efficiency, but will also make further breakthroughs in intelligence, environmental protection and low cost, further opening up a broader market space.