The safety features included in a silicon machine can vary depending on the manufacturer and model. However, here are some common safety features that are typically found in silicon machines:

Common Safety Features in Silicon Machines

Emergency Stop Buttons:

Easily accessible emergency stop buttons that immediately halt the machine's operation to prevent accidents or injuries.

Safety Interlocks:

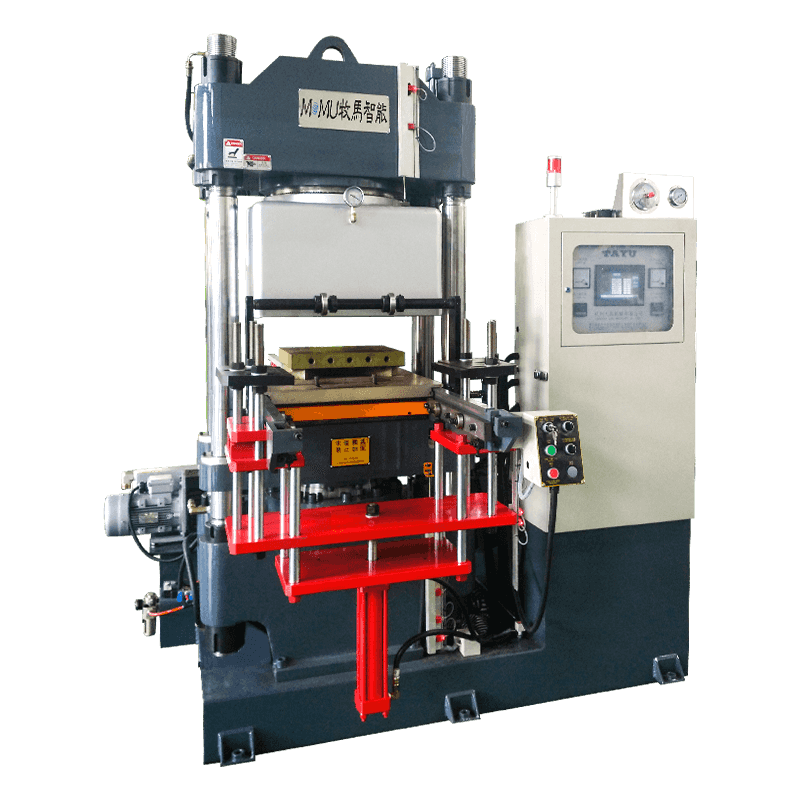

![]()

Interlocking mechanisms that prevent the machine from operating if safety guards or doors are not properly closed.

Safety Guards and Enclosures:

Protective guards and enclosures around moving parts to prevent accidental contact by operators.

Light Curtains and Sensors:

Optical sensors or light curtains t

hat detect the presence of objects or people in hazardous areas and stop the machine if the safety zone is breached.

Automatic Shutoff Mechanisms:

Automatic shutoff features that activate in case of abnormal conditions such as overheating, overloading, or loss of power.

Warning Alarms and Indicators:

Audible and visual alarms that alert operators to potential hazards or malfunctions.

Lockout/Tagout (LOTO) Provisions:

Systems that ensure the machine cannot be accidentally powered on during maintenance or repair by locking and tagging out the energy sources.

Pressure and Temperature Controls:

Safety controls that monitor and regulate pressure and temperature to prevent dangerous operating conditions.

Safety Protocols and Software:

Integrated safety software that enforces operational limits and safety protocols, ensuring the machine operates within safe parameters.

Training and Documentation:

Comprehensive training programs and detailed documentation on safe operation, maintenance, and emergency procedures.

Additional Advanced Safety Features

Machine Vision Systems:

Cameras and vision systems that detect unsafe conditions or operator errors and stop the machine automatically.

Redundant Safety Systems:

Multiple safety systems that provide backup protection in case one system fails.

Protective Circuitry:

Electrical circuitry designed to prevent short circuits, overloads, and other electrical hazards.

Fail-Safe Design:

Design features that ensure the machine defaults to a safe state in the event of a malfunction or power loss.

Industry-Specific Safety Features

Depending on the specific application and industry, additional safety features might be included to address unique risks. For example:

Cleanroom Compatibility:

In semiconductor manufacturing, machines may have features to maintain cleanroom standards and prevent contamination.

Explosion-Proof Design:

In environments where flammable materials are processed, machines may be designed to prevent ignition sources and contain explosions.

Radiation Shields:

In applications involving radiation, appropriate shielding to protect operators from exposure.

Compliance and Certification

Machines often need to comply with industry-specific safety standards and regulations, such as:

ISO (International Organization for Standardization) Standards:

Compliance with relevant ISO safety standards for machinery.

OSHA (Occupational Safety and Health Administration) Regulations:

Adherence to OSHA safety requirements in the United States.

CE Marking:

Compliance with European Union safety, health, and environmental protection requirements.

Understanding these safety features and ensuring they are implemented can significantly reduce the risk of accidents and injuries in the workplace.