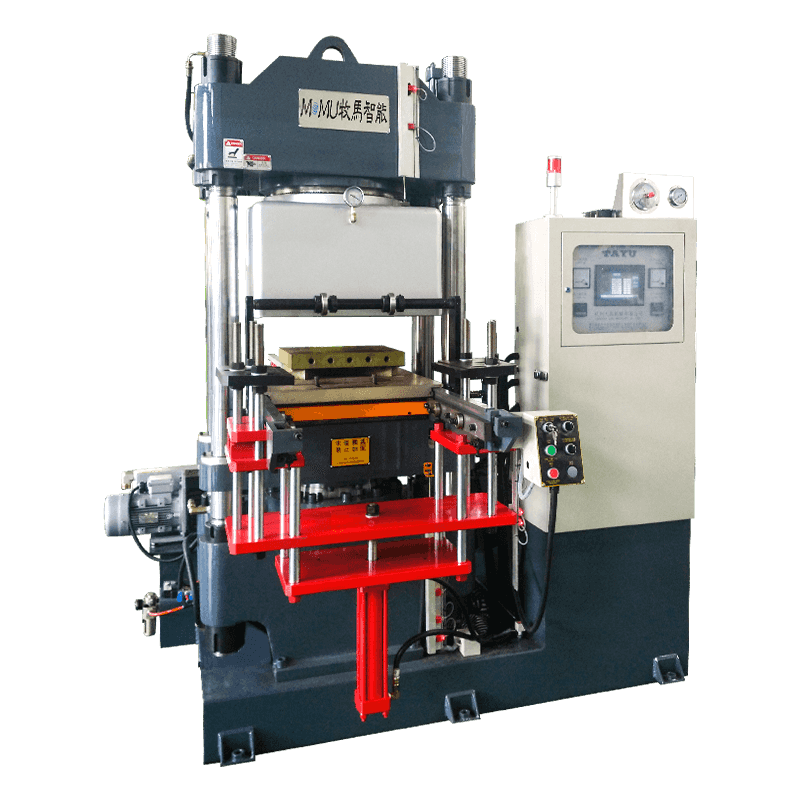

How does a rubber compression molding machine ensure that the rubber material is evenly distributed within the mold?

Rubber compression molding machines employ a series of clever design and operational techniques to achieve uniform distribution of rubber material within the mold cavity. This is a critical step in the production of high-quality rubber products.

Precise material loading:

The process begins with precise control of the material loading.

Based on product requirements and mold design, operators carefully calculate the required amount of rubber material.

Mechanical arms or automated feeding systems then place the rubber material evenly within the mold cavity.

This ensures a uniform foundation for the rubber distribution from the initial stage.

Uniform compression:

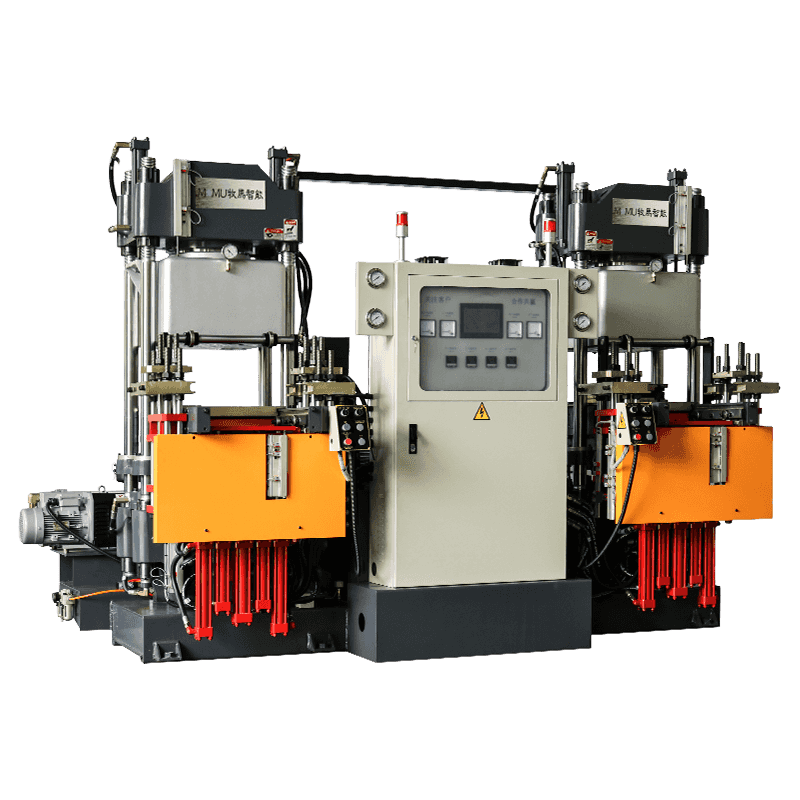

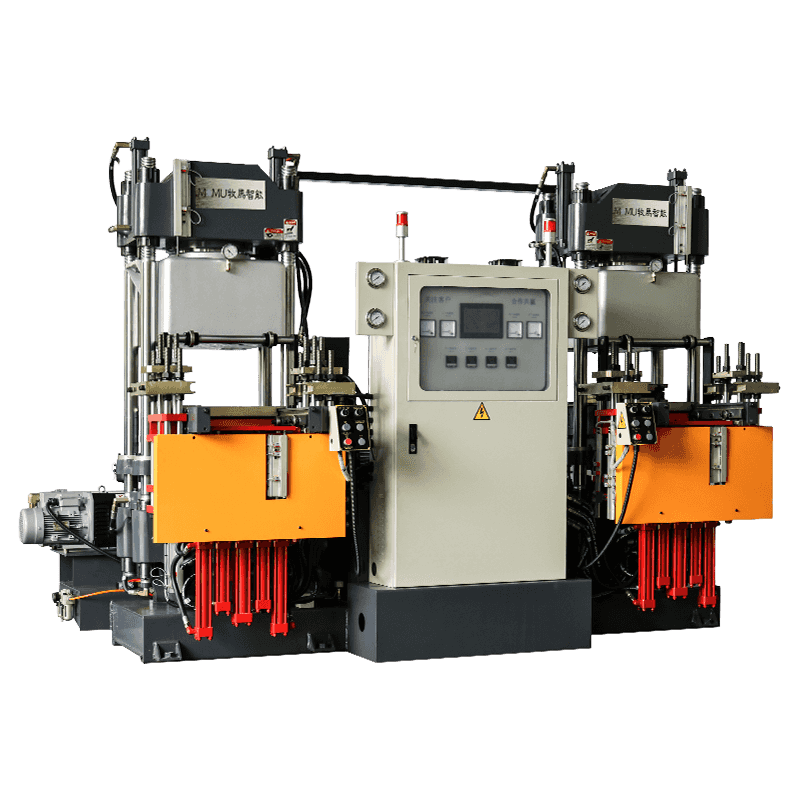

During compression, the machine follows a preset program to apply smooth and uniform compression to the mold using hydraulic cylinders or other drive mechanism.

This ensures that the rubber material fills every corner of the mold cavity and eliminates air pockets and unevenness within the material to a certain extent.

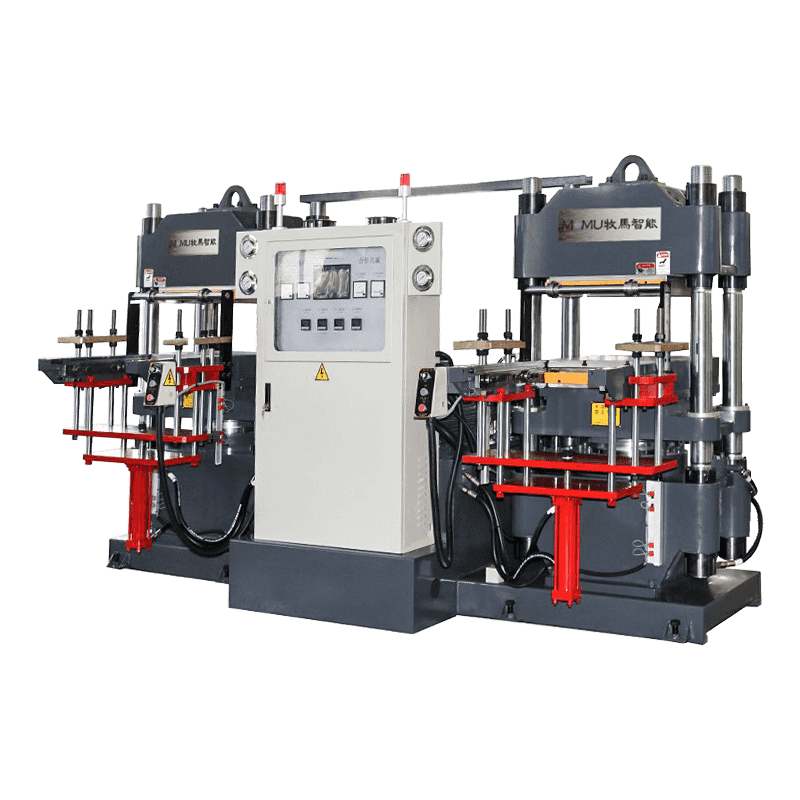

Mold design and manufacturing:

The design and manufacturing quality of the mold also play a crucial role in achieving uniform rubber distribution.

High-quality molds accurately match the product shape and provide uniform pressure distribution during compression.

Surface treatment and lubrication of the mold can also effectively reduce friction between the rubber material and the mold, further promoting uniform flow and distribution of the material.

Key takeaways:

The techniques used to achieve uniform rubber distribution in rubber compression molding machines are both scientific and practical.

These seemingly simple operations and designs embody a wealth of industrial wisdom.

It is these meticulous processes that enable rubber products to be accurately molded and meet our daily needs.