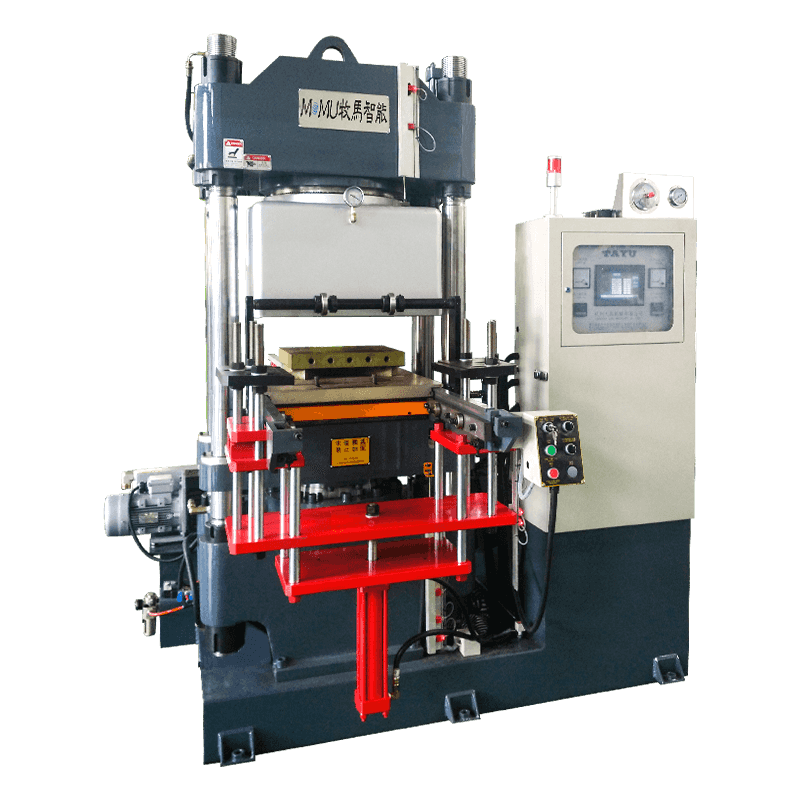

Why does the rubber compression molding machine use a double cylinder design to achieve stable pressure?

Have you ever wondered how rubber compression molding machines maintain consistent pressure under high load to produce high-quality rubber products of various shapes? The answer lies in their dual-cylinder design. Today, let's delve into the science and practical applications behind this ingenious design.

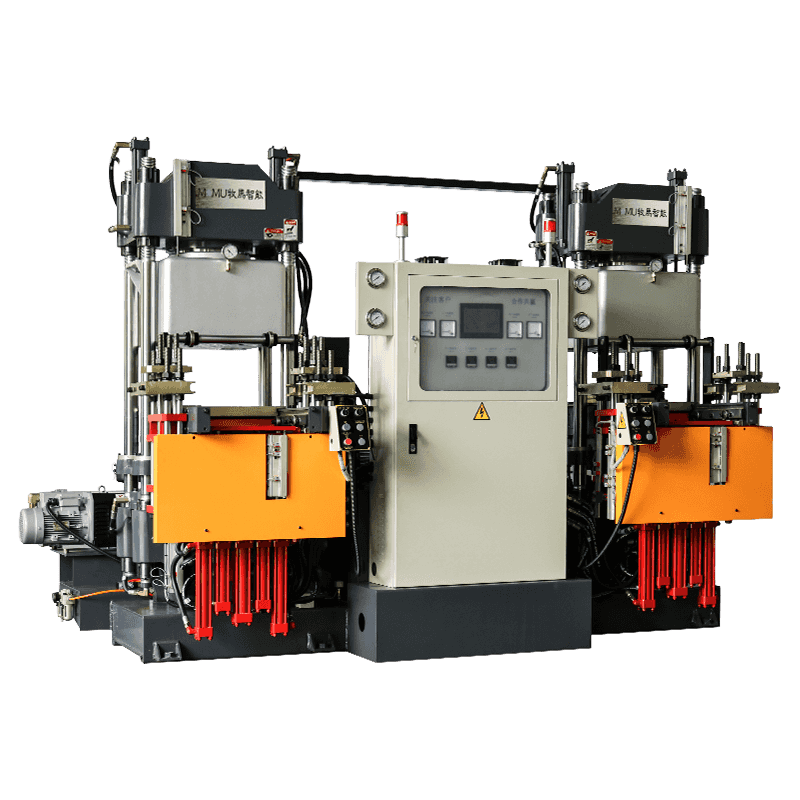

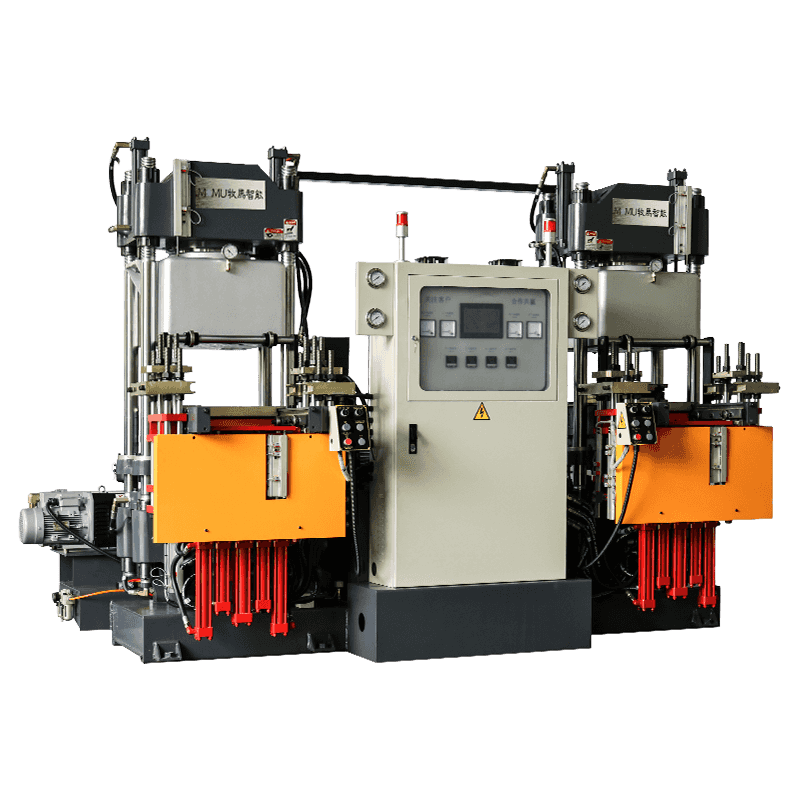

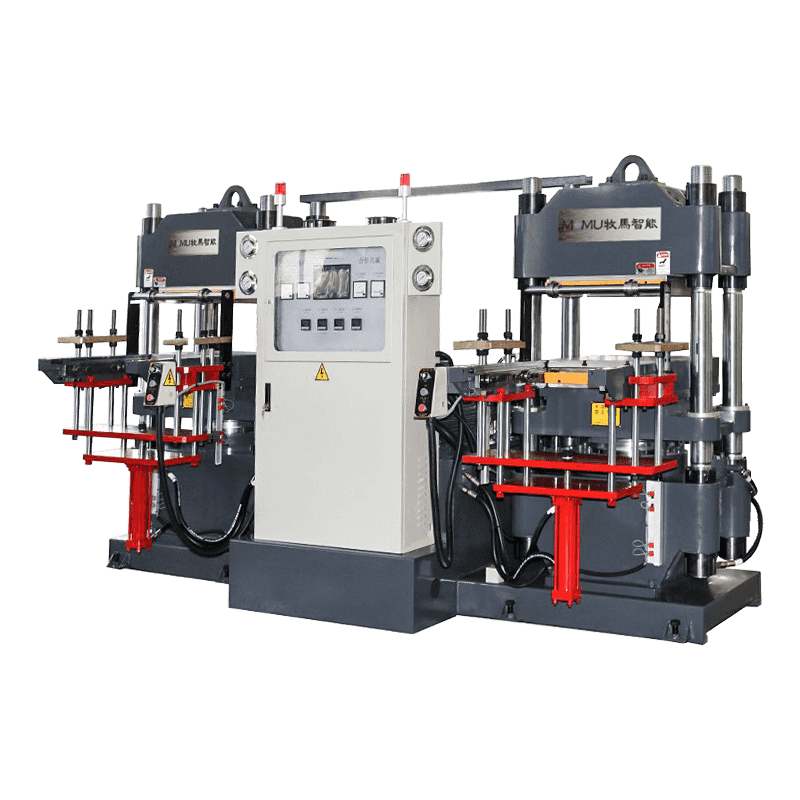

From a mechanical perspective, the dual-cylinder design enables the machine to create a more balanced force field during the compression process. In rubber compression molding, the material inside the mold needs to be subjected to uniform and stable pressure to ensure product quality and precision. The dual cylinders work synchronously to generate equal and smooth thrust on both sides of the mold, avoiding the uneven pressure problems that may arise with a single cylinder.

In high-pressure working environments, a single cylinder may experience performance degradation or failure due to uneven force distribution or material fatigue. The dual-cylinder design, on the other hand, can reduce the load on each cylinder by sharing and balancing the pressure. This enhances the machine's stability and extends its service life.

The dual-cylinder design offers better adaptability. Different rubber materials and product shapes have different pressure requirements. The dual-cylinder design allows the machine to adjust the working pressure and speed according to actual needs, meeting the molding requirements of different materials and products.

Exploring the dual-cylinder design of rubber compression molding machines is like uncovering the secrets of an ingenious mechanical device. It is not some high-tech black magic, but a practical technology designed to ensure the quality of rubber products. Through the clever coordination of the dual cylinders, rubber compression molding machines can apply pressure smoothly and precisely, ensuring that each product is accurately molded.