In modern manufacturing, vacuum compression molding machines, as an important production equipment, are driving technological innovation in many industries. So, how did the vacuum compression molding machine change the development direction of the manufacturing industry?

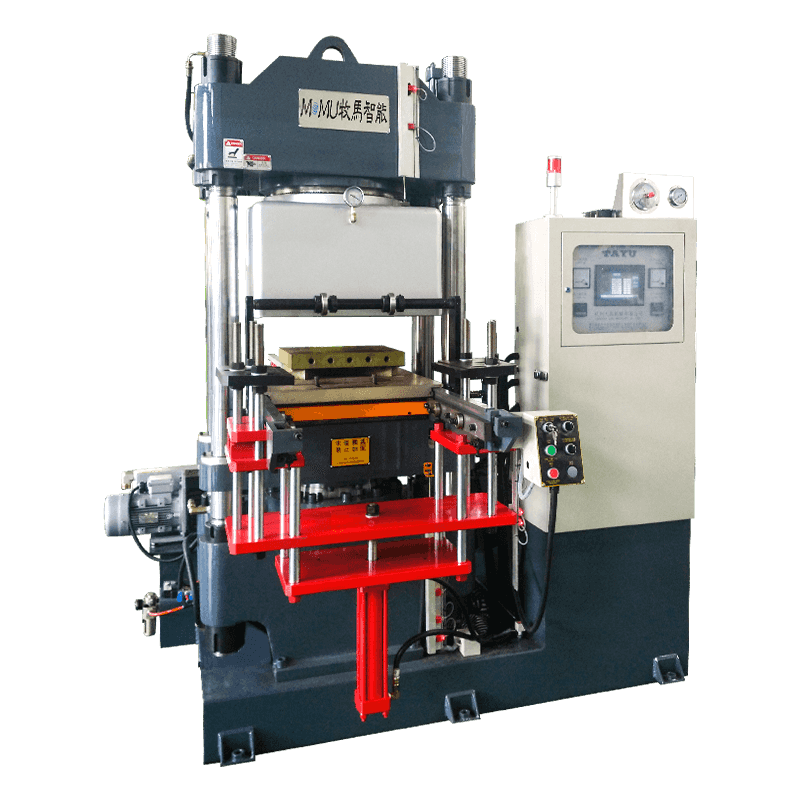

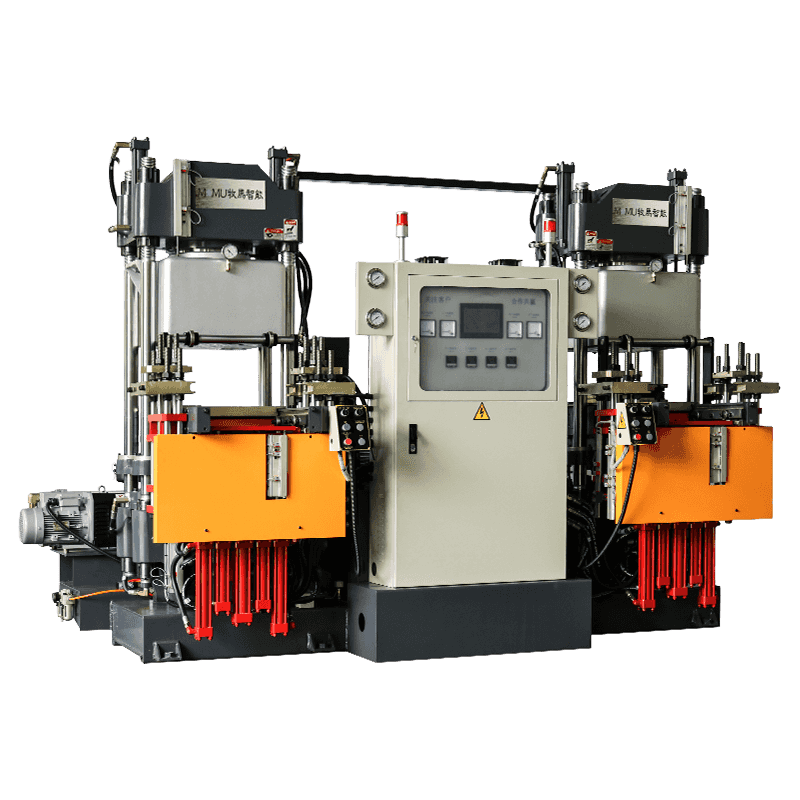

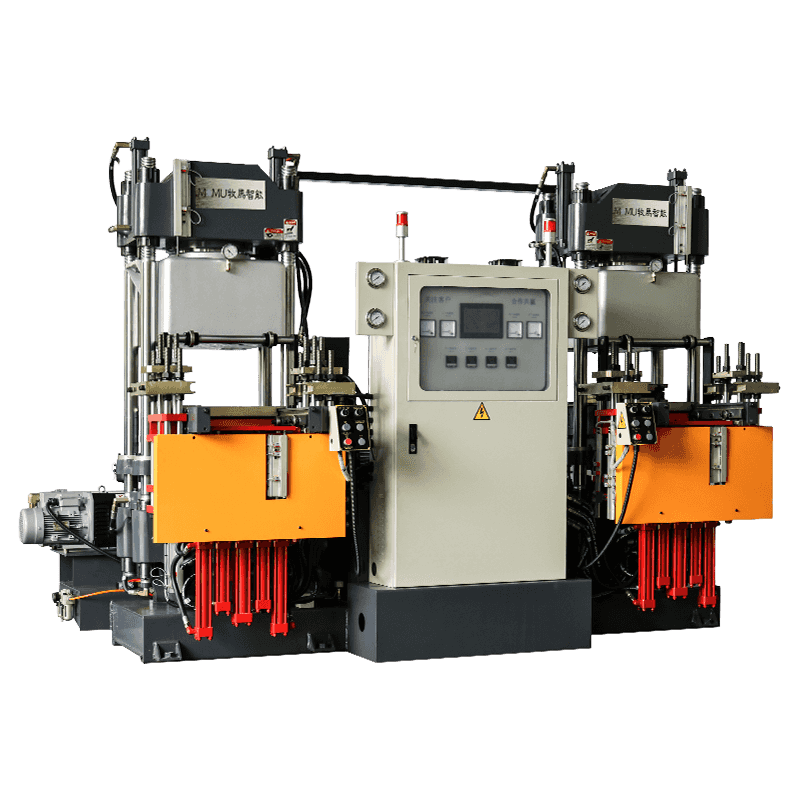

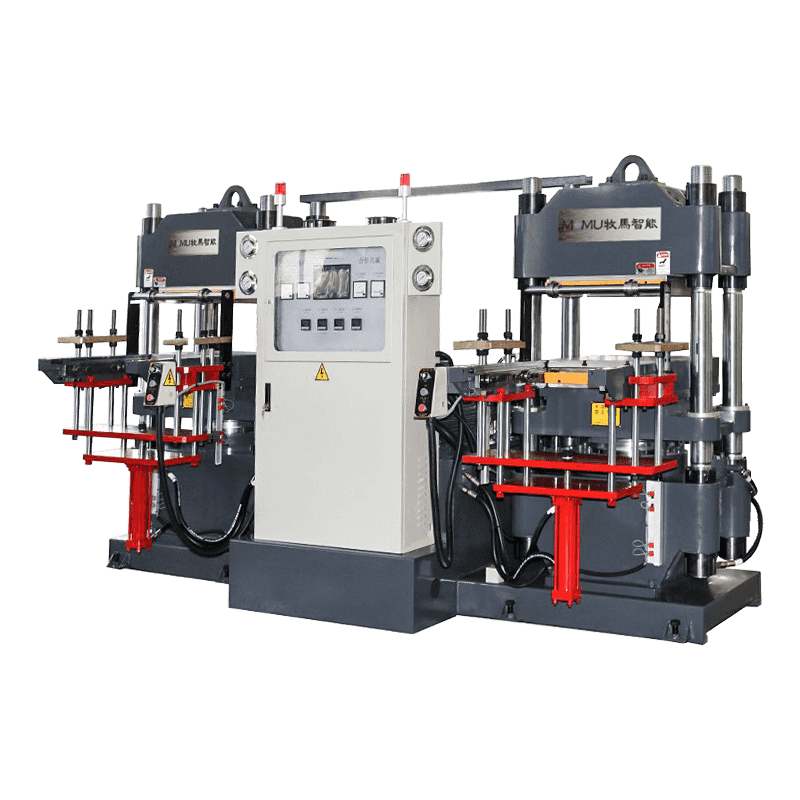

Vacuum compression molding machine is a device that heats and compresses materials in a vacuum environment. This equipment avoids the generation of bubbles and defects during the molding process by removing air and other gases in a vacuum environment, thereby ensuring high precision and high quality of the product. After the material is heated to a softened state, a pressurized mold applies pressure and is finally formed into the desired shape. Vacuum compression molding machines are widely used in various high-demand manufacturing fields, such as aerospace, automotive industry, and electronic product manufacturing.

Vacuum compression molding machines have many advantages in manufacturing. First, it can significantly improve product accuracy and consistency, especially when producing parts with complex shapes and high precision requirements. Secondly, the molding process in a vacuum environment can reduce bubbles and defects inside the material, thereby improving the mechanical properties and durability of the product. In addition, the vacuum compression molding machine can also reduce material waste, improve production efficiency, and make the manufacturing process more environmentally friendly and economical. These advantages make this equipment widely used in high-end manufacturing.

As the manufacturing industry's demand for high-performance materials and high-precision components increases, vacuum compression molding machines are becoming an important tool to promote technology upgrades. By using this equipment, manufacturers can produce more complex and sophisticated products to meet the demand for high-quality components in emerging technology areas. For example, in the aerospace industry, vacuum compression molding machines are used to create lightweight composite parts to improve aircraft fuel efficiency and overall performance. In addition, in electronic product manufacturing, this equipment is also widely used to produce high-density circuit boards and precision electronic components, promoting the miniaturization and functional integration of electronic products.

Vacuum compression molding machines are promoting technological innovation in the manufacturing industry with their unique advantages. By improving product quality and production efficiency, this equipment not only meets the needs of high-end manufacturing for high-performance products, but also provides technical support for the future development of the manufacturing industry. With the further improvement of equipment and expansion of applications, vacuum compression molding machines will play a key role in more fields.