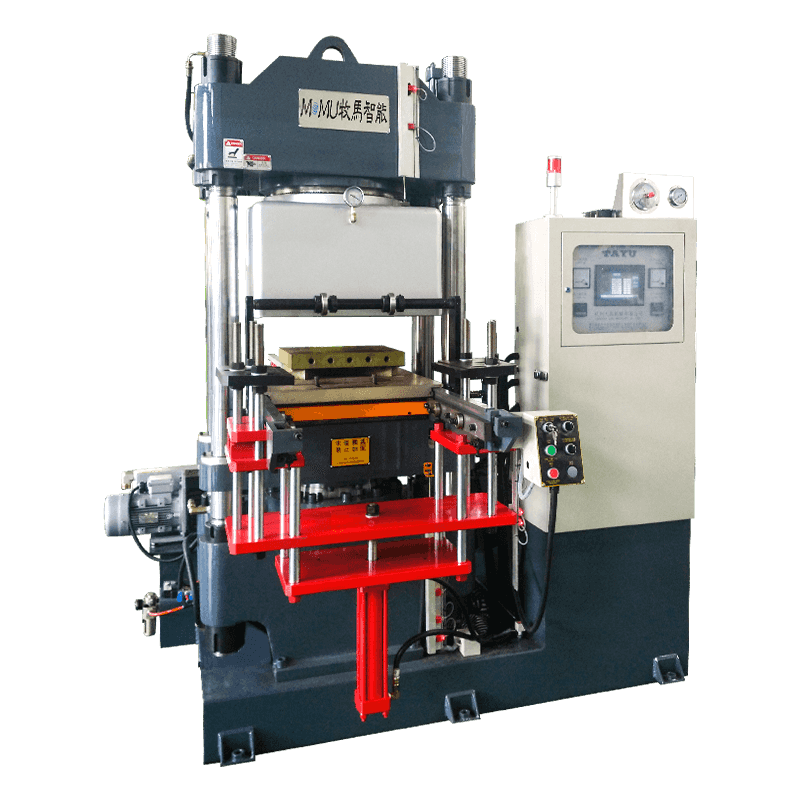

Rubber injection molding machine is a kind of equipment used to process rubber products, which is widely used in automobile, home appliance, medical, electronics and other industries. It can make rubber products with complex shapes and excellent performance by heating, plasticizing, injection and other processes.

The working principle of rubber injection molding machine is similar to that of plastic injection molding machine, but due to the characteristics of rubber materials, there are certain differences in its process flow and equipment structure. Generally speaking, the workflow of rubber injection molding machine includes the following steps:

The raw rubber (or mixed rubber) is fed into the feeding barrel through the feeding device. The screw in the feeding barrel pushes the rubber forward while rotating, and heats the rubber through an electric heater or an oil heater to make it reach a suitable plasticized state.

After the rubber is fully plasticized, the injection device starts to work and quickly injects the rubber into the mold. The mold consists of two parts, the upper and lower parts, and the rubber enters the cavity through the gate of the mold and fills the cavity.

When the rubber is injected into the mold, the mold is closed, and the rubber in the mold is vulcanized under high temperature and high pressure conditions. Vulcanization is a key step in the production of rubber products. Through vulcanization, the molecular structure of the rubber material undergoes a cross-linking reaction, thereby obtaining the final mechanical properties and heat resistance, aging resistance and other characteristics.

After vulcanization is completed, the mold is opened and the product is removed from the mold mechanically or manually. The product may require further trimming or processing, such as removing excess flash or surface cleaning.

![]()

Rubber injection molding machines are widely used in many industries, especially in situations where high-precision and complex-shaped rubber products need to be mass-produced. Here are some of the main application areas:

In automobile manufacturing, rubber injection molding machines are used to produce various key components such as seals, shock absorbers, rubber gaskets, etc. These components are required to have good heat resistance, oil resistance, and aging resistance to meet the needs of automobile use in complex environments.

A large number of rubber parts are required in electronic equipment, such as buttons, seals, cable sheaths, etc. Rubber injection molding machines can efficiently produce these parts to ensure that they have excellent insulation, waterproof and wear resistance.

In medical devices, rubber parts such as seals, syringe pistons, etc. need to have high cleanliness and biocompatibility. Rubber injection molding machines can precisely control the molding process and produce products that meet the strict standards of the medical industry.

Many components in home appliances, such as seals, gaskets, buttons, etc., are manufactured by rubber injection molding machines. Modern home appliances require high efficiency and long life, and the quality of rubber parts directly affects the overall performance of the product.

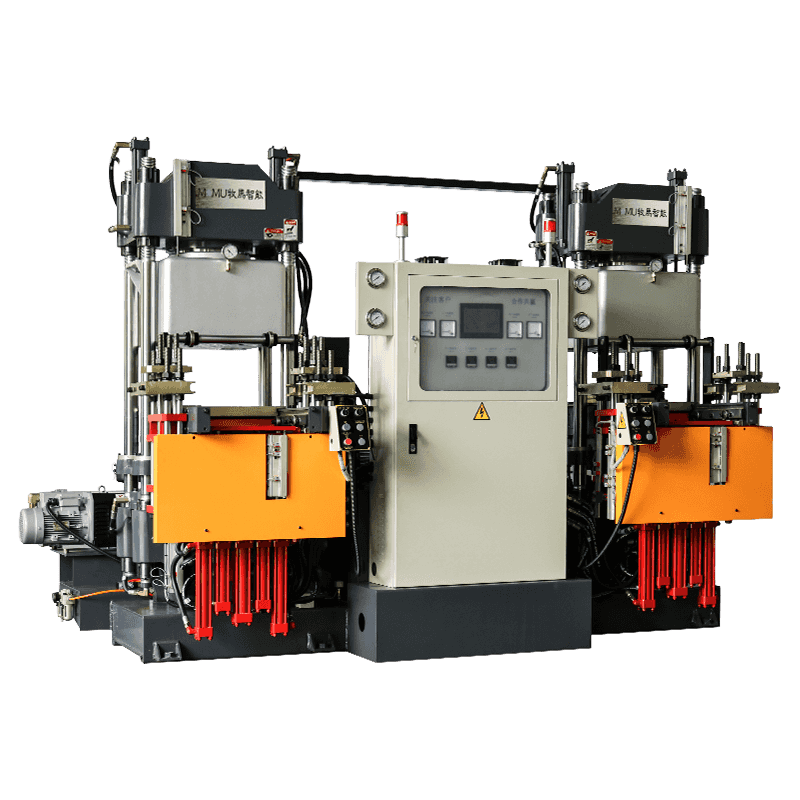

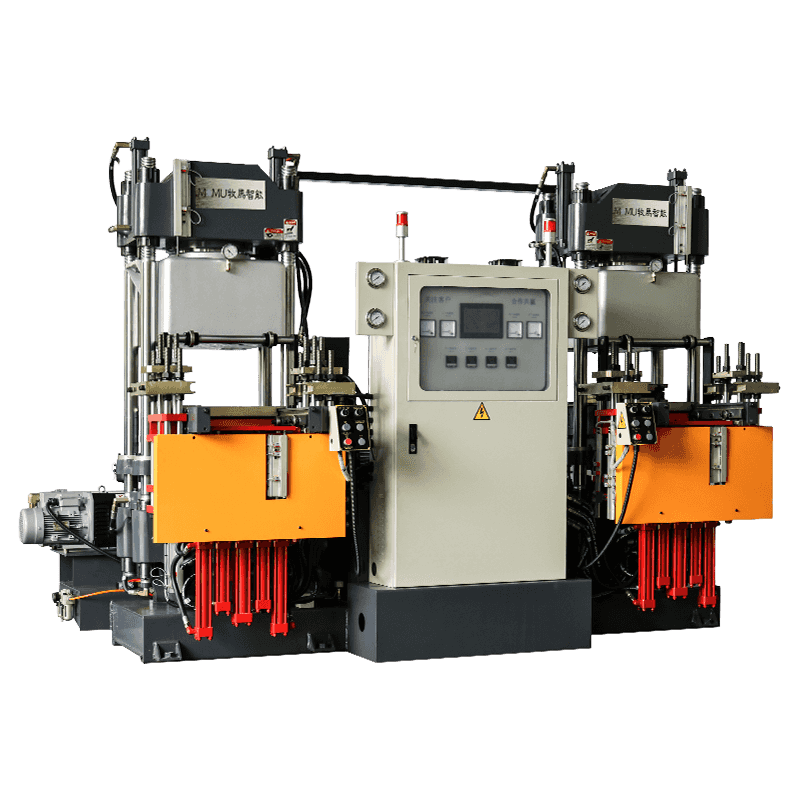

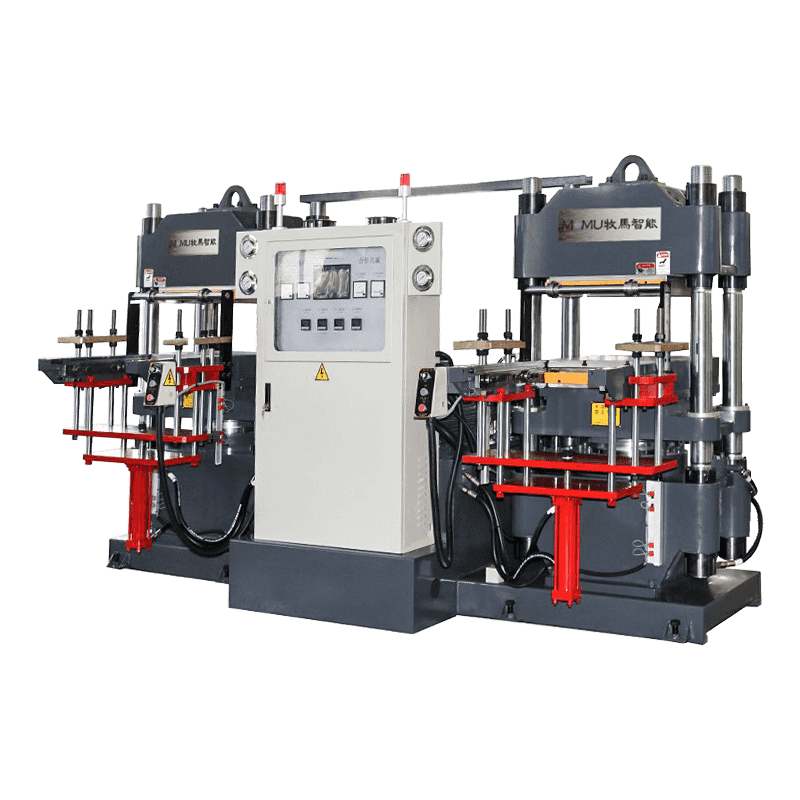

With the development of industrial technology, rubber injection molding machines are developing in the direction of intelligence, energy saving and environmental protection. Future development trends mainly include the following aspects:

Introducing intelligent control systems to achieve automatic monitoring and adjustment of the production process, improve production efficiency and product quality.

Adopting new heating technology and energy-saving design to reduce energy consumption, while reducing waste and harmful substances in the production process.

Developing multifunctional rubber injection molding machines that can handle different types of rubber materials and adapt to a wider range of application needs.

With the development of new rubber materials, injection molding machines are also constantly improving to adapt to the processing needs of these materials, thereby producing rubber products with better performance.

As an important equipment for the production of rubber products, rubber injection molding machines are constantly developing and improving. Its high efficiency, precision and adaptability make it occupy an important position in many industries. In the future, with the advancement of technology and changes in market demand, rubber injection molding machines will play an irreplaceable role in a wider range of fields.