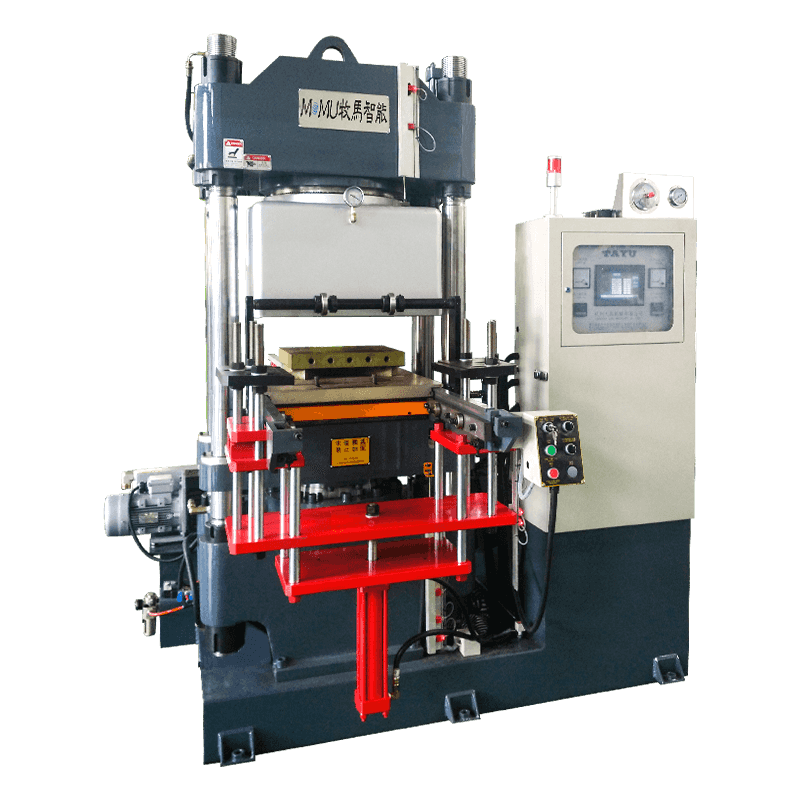

What effect does precision machining have on special machines for power insulators?

Precision machining plays a critical role in the manufacturing of special machine for power insulators, impacting various aspects of the process and the final product. Here are some key points:

Ensuring dimensional and shape accuracy:

Precision machining ensures that critical components of the machine, such as the transmission system, positioning system, fixtures, and guide mechanisms, meet the design requirements in terms of size and shape accuracy.

The accuracy of these components directly affects the machine's operational stability and processing precision.

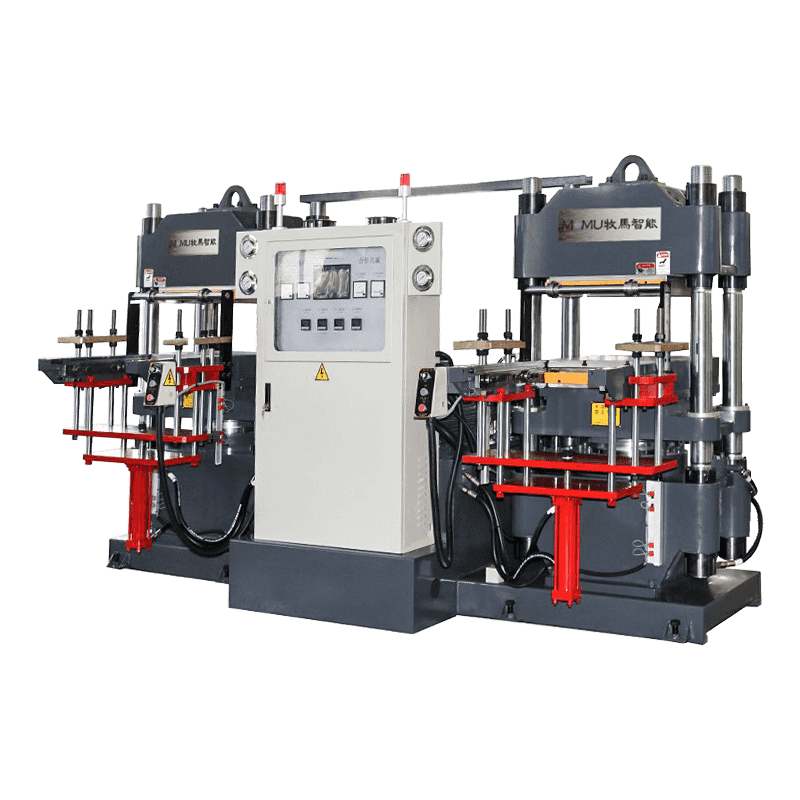

Improving surface quality:

Precision machining enhances the surface finish and flatness of components, reducing surface roughness and burrs.

This ensures better sealing and transmission performance between components.

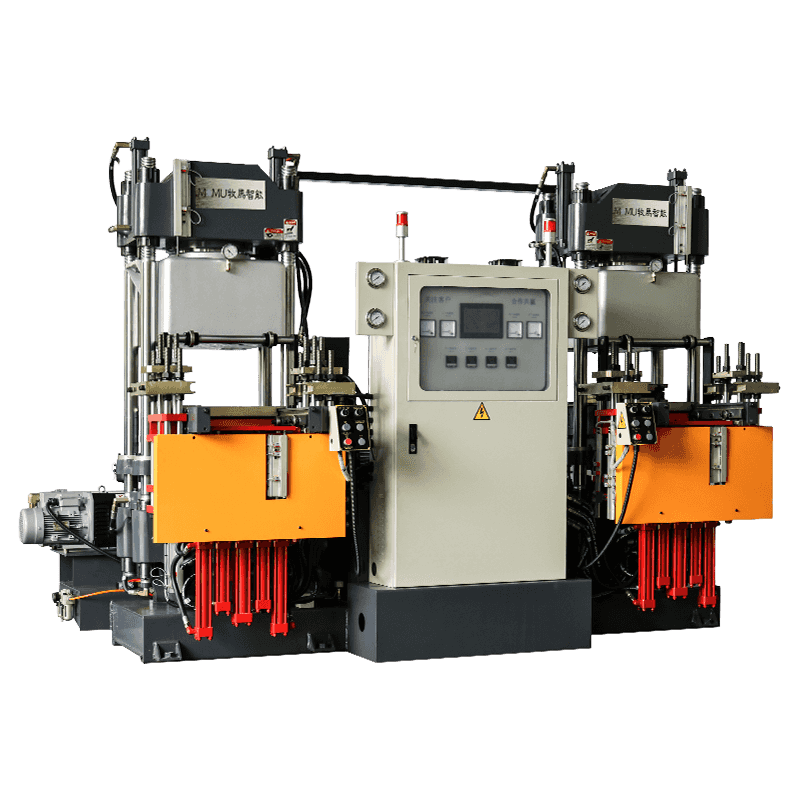

Ensuring dimensional consistency and geometric accuracy:

Precision machining guarantees the dimensional consistency and geometric accuracy of components.

This leads to higher fitting accuracy during assembly, smoother assembly process, and improved machine assembly efficiency and quality stability.

Reducing machining time and improving production efficiency:

Precision machining reduces machining allowance and the need for subsequent grinding, shortening the processing cycle and improving production efficiency.

By improving the accuracy and quality of components, it also reduces the time required for debugging and calibration during assembly, further enhancing the overall assembly efficiency and productivity.

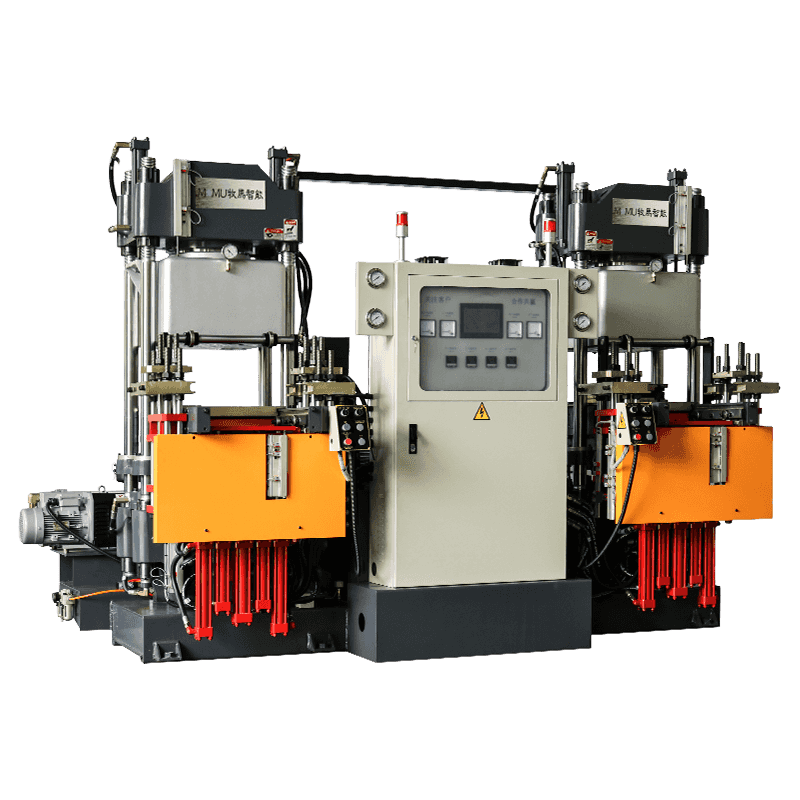

Guaranteeing overall performance and reliability:

Precision machining ensures that the accuracy and quality of all components of the power insulator special-purpose machine meet the design requirements.

This leads to improved overall performance stability, operational reliability, and processing accuracy of the machine, which is crucial for achieving high-quality processing and production.

In conclusion, precision machining is of critical importance to the manufacturing of power insulator special-purpose machines. By improving the precision and quality of components, it enhances the overall performance, efficiency, and reliability of the machine, contributing significantly to high-quality production.