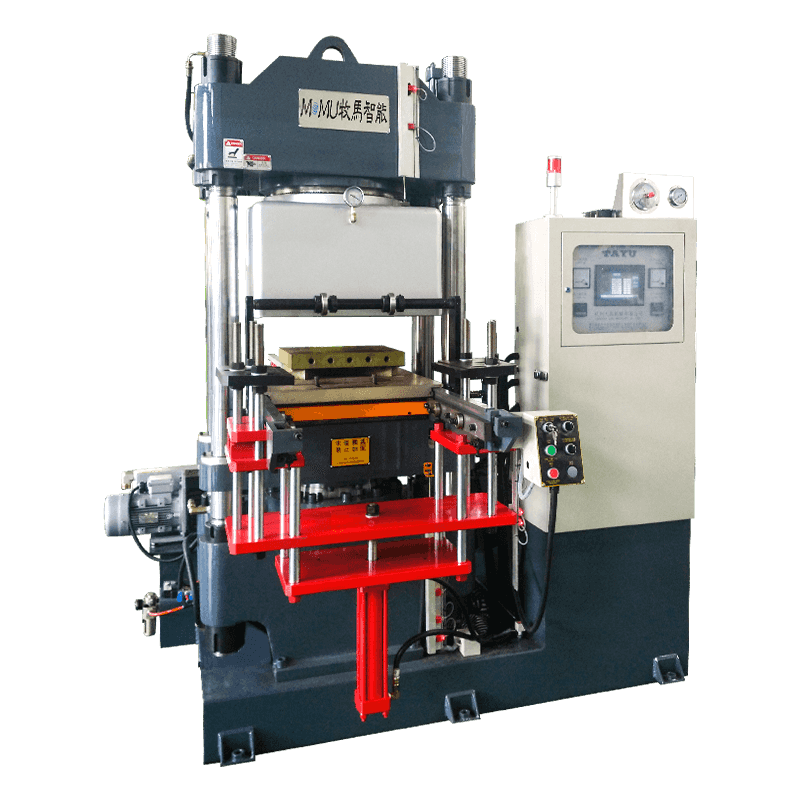

How to ensure the accuracy and quality of special machines for power insulators?

To ensure the accuracy and quality of the special machine for power insulators, the following key measures can be taken:

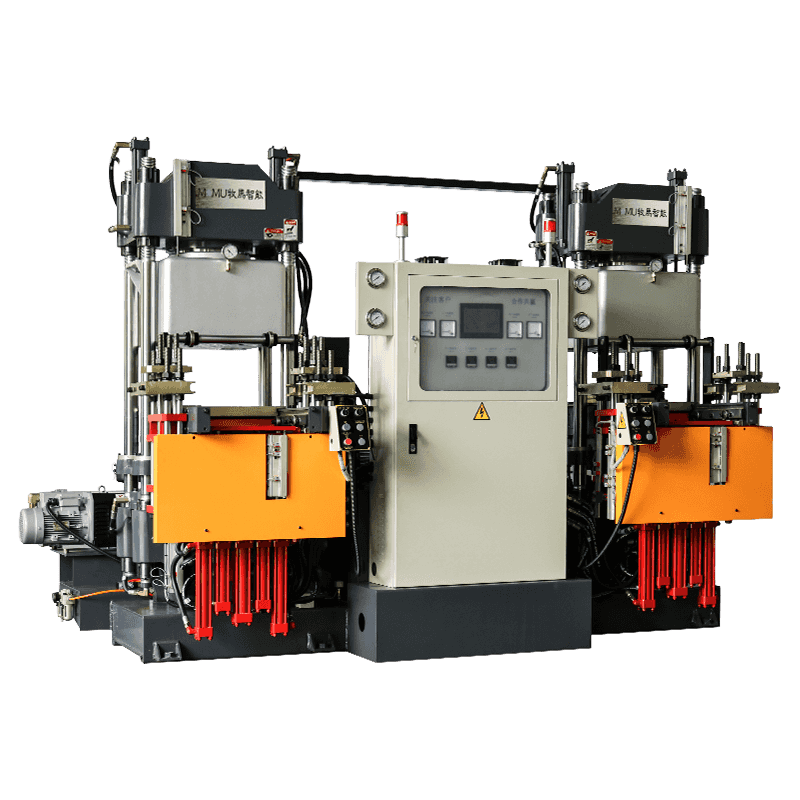

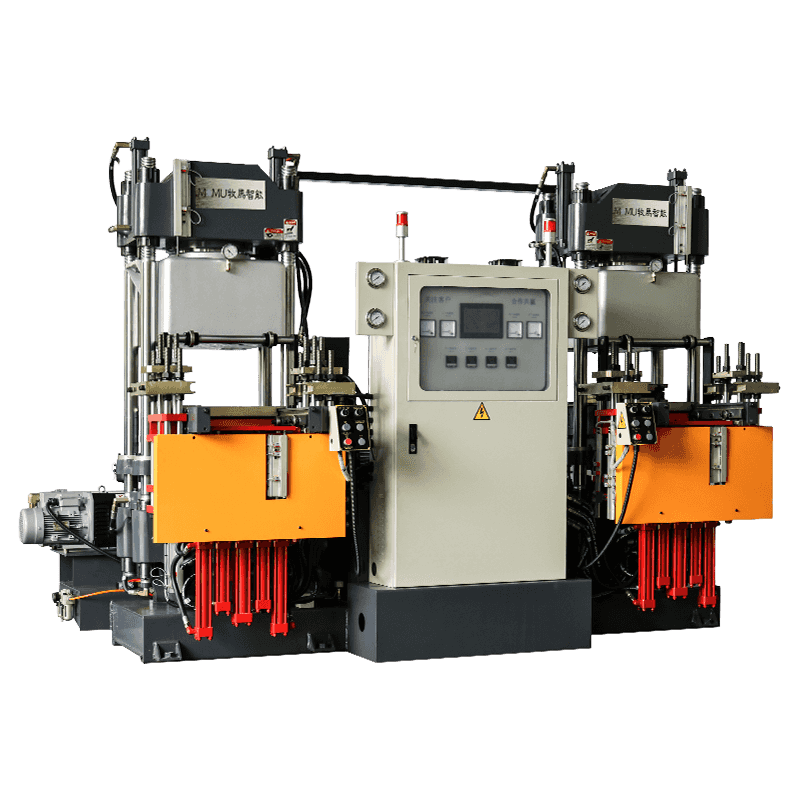

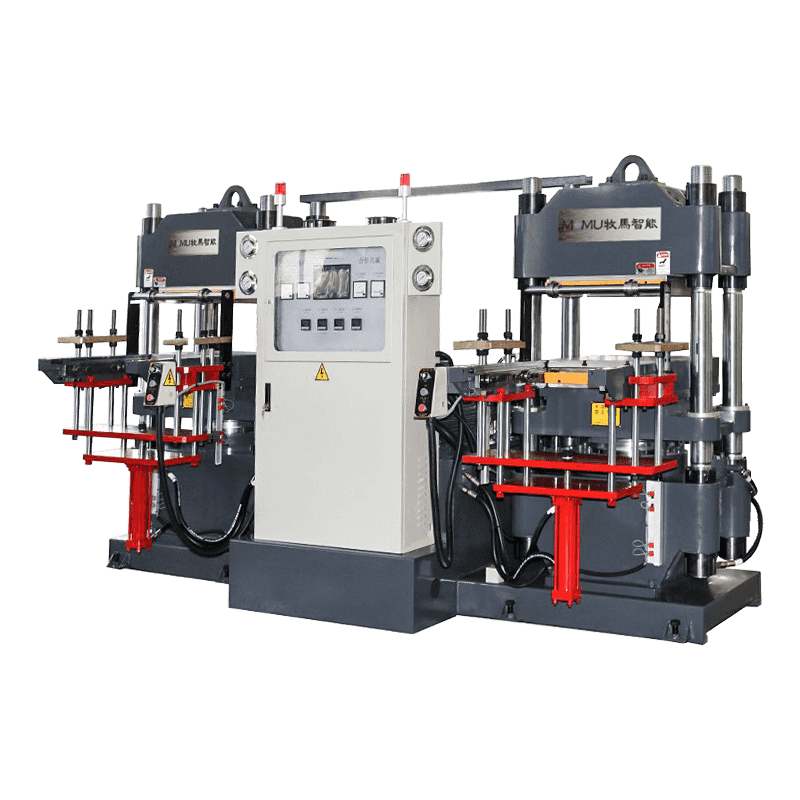

Selecting High-Quality Raw Materials and Components: Especially focusing on critical components and core parts such as motors, transmission devices, and control systems. Ensure these components possess excellent wear resistance, stability, and reliability.

Establishing Strict Production Processes and Quality Management Systems: Ensure that each production process strictly adheres to standardized operations to avoid quality issues arising from improper production processes.

Utilizing Advanced Processing Equipment and Techniques: Employ advanced machining equipment and techniques for precise processing and assembly of critical components. Ensure that each part meets the required dimensional and shape accuracy without errors during assembly.

Implementing Comprehensive Quality Inspection and Control Measures: This includes inspections of raw materials, components, semi-finished products, and finished products. Utilize various inspection methods and techniques to ensure products comply with relevant standards and requirements.

Continuously Optimizing Product Performance and Process Flow: Introduce advanced technologies and processes to improve product accuracy and quality. Based on user feedback and market demand, promptly adjust product structure and design to enhance competitiveness and market share.

Effectively ensuring the accuracy and quality of specialized machinery for power insulators will improve product performance stability and reliability.